The AM-MG100 Inspection Systems are our line of mechanical gauging inspection machines that keeps the cost of inspection and machinery low while still allowing for certification of your parts. This inspection system is designed around your product and work well on stamped parts like washers, conical parts, and much more.

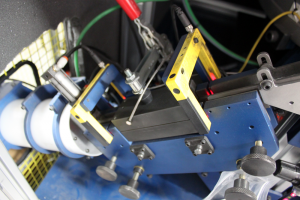

Each AM-MG100 Inspection Machines are designed around the sorting and inspection needs of our clients. While each part will require a different type of gauging system, the general design concepts logic are very similar. In the following example, the parts were fed into a fully adjustable feeding system and then into a gauge. The main inspection qualification that was being checked in this scenario was bent parts. Due to the design requirements set by the client, this was was the main purpose of this AM-MG100 Inspection Machine, but this is not the limitation of the system. Multiple subsystems can be added to this including:

Each AM-MG100 Inspection Machines are designed around the sorting and inspection needs of our clients. While each part will require a different type of gauging system, the general design concepts logic are very similar. In the following example, the parts were fed into a fully adjustable feeding system and then into a gauge. The main inspection qualification that was being checked in this scenario was bent parts. Due to the design requirements set by the client, this was was the main purpose of this AM-MG100 Inspection Machine, but this is not the limitation of the system. Multiple subsystems can be added to this including:

- Eddy Current

- Vision

- Lasers

Length – As needed

Length – As needed