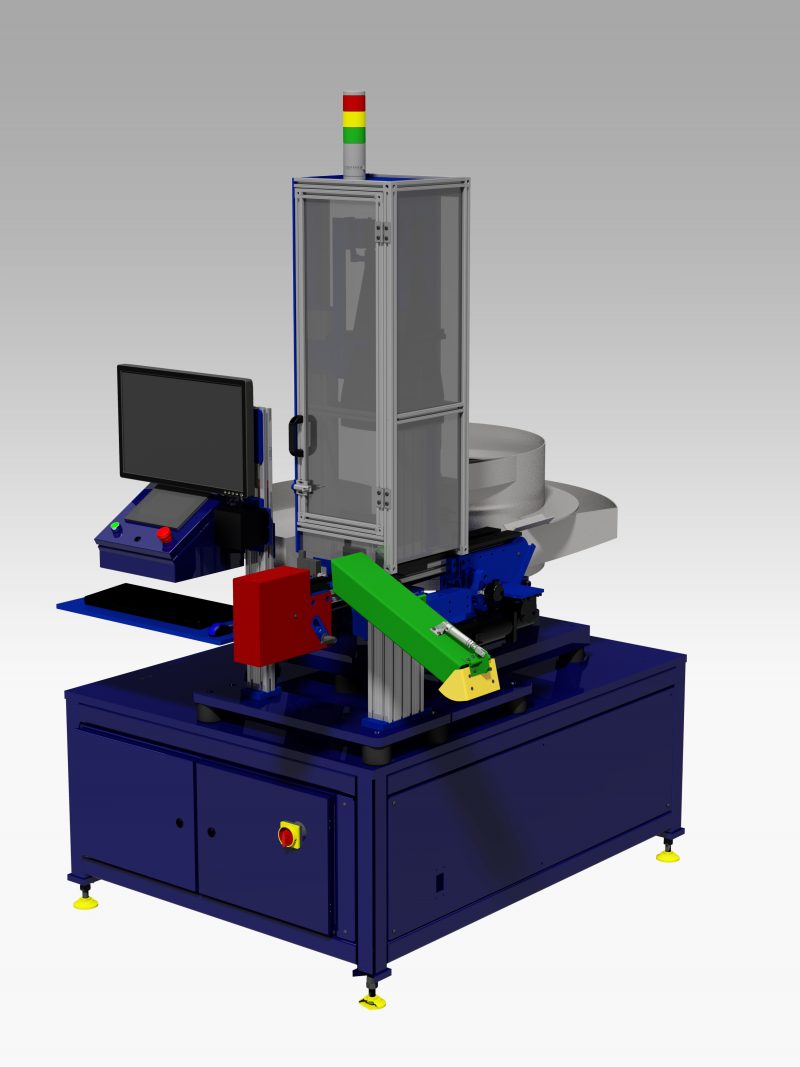

Using gravity to handle the part during inspection introduces the variable of friction, timing, oily surfaces, and tumbling parts to the inspection process. The AV-B100-V belt allows us to inspect headless parts with precision and accuracy that exceeds the competition by keeping that ability to track and trace your part through the inspection process. While keeping cost low and adding another solution to our product line of inspection machinery, the AV-B100-V is a great solution for many different ranges of parts.

Contact USAV Series Brochure (Eng.) AV Series Brochure (Esp.)

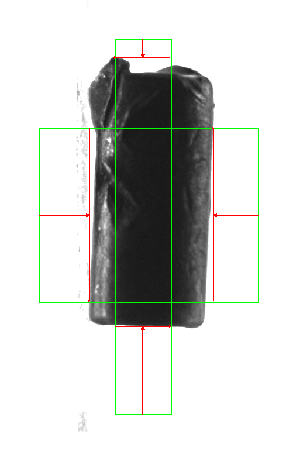

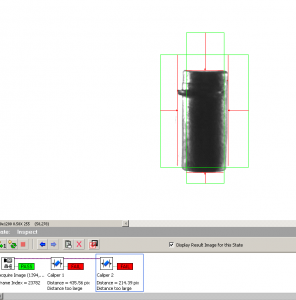

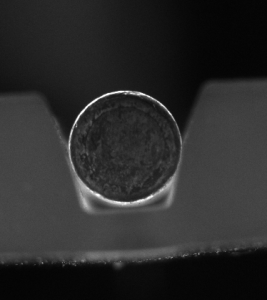

The AV-B100-V Inspection Machine is a “V-Belt” high speed inspection machine the incorporates multiple inspection methods while tracking the part through the entire process. The subsystem that sets this inspection machine apart from the competition is the horizontal V-track conveyor system. This system carries the product through the inspection process allowing inspection all around the parts. During this process, multiple inspection methods can be used to verify your part including:

- Vision

- Image Splitting

- Eddy Current

- Lasers

- Physical Gauging

Studs

Studs