“William Bennett, President at Attica Automation, says “Here at Attica Automation, we have developed and patented automated inspection systems and processes that gives us a reputation for knowledge and ingenuity that surpasses the competition. In our current economy, companies have found that repairing and/or upgrading their worn out, obsolete, and old equipment is more cost effective than purchasing a new machine.”

“William Bennett, President at Attica Automation, says “Here at Attica Automation, we have developed and patented automated inspection systems and processes that gives us a reputation for knowledge and ingenuity that surpasses the competition. In our current economy, companies have found that repairing and/or upgrading their worn out, obsolete, and old equipment is more cost effective than purchasing a new machine.”

Here are some symptoms that may warrant a rebuild or upgrade to your current inspection systems:

- Inspection and automation systems not accurate

- Malfunctioning parts due to “wear and tear”

- Inspection and automation system with outdated or obsolete technology

- Manual inspection and automation processes prone to errors

- Old machines no longer usable due to lack of production needs or machine errors.

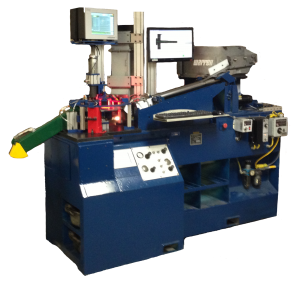

Our solution to these problems is our vision system, Attica Vision™, as well as our parts handling and feeding processes, Attica Drive™. We started developing our Attica Vision™ and Attica Drive™ systems 20 years ago. Over the years, these systems have been developed into an enterprise solution that incorporates some of the newest and most innovative technologies including, but not limited to, the following:

- Custom Lens Technology

- Attica Trigger Buffer Delay™ software

- Attica Drive™ feeding system

- Attica Vision™ system

- Laser Sensors

- Eddy Current

An example of this would be a recent project we performed on a Pace fastener inspection system. The old optic inspection system was removed, and it was replaced with the Attica Vision™ and Attica Drive™ systems. This included Eddy Current for cracked head inspection.”